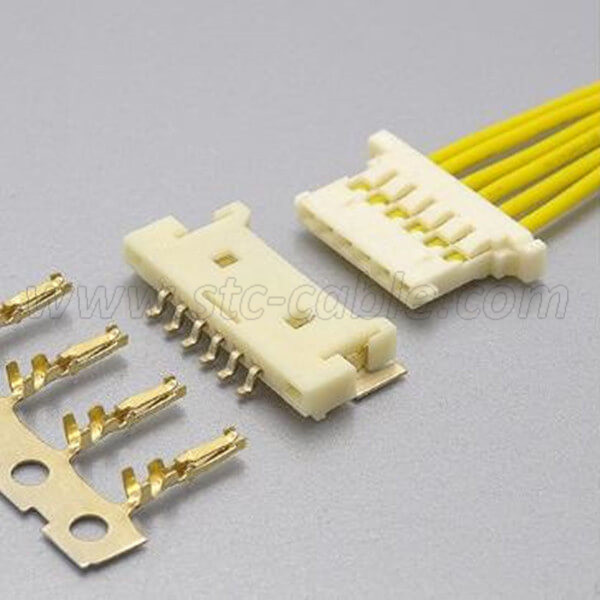

1.25mm Molex 51146 wire to board connector wire harness

Applications:

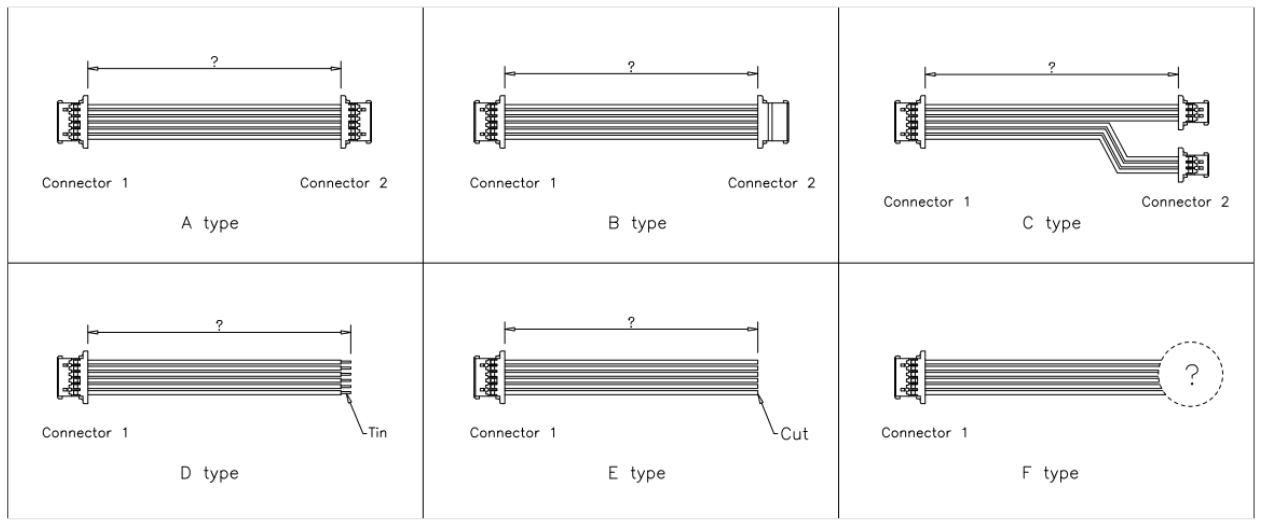

- Length & Termination customized

- Pitch: 1.25mm

- pins: 2 to 16, 20, 30 positions

- Material: Nylon UL 94V0 (Lead Free)

- Contact: Phosphor Bronze

- Finish: Plated Tin or Gold Flash Lead over Nickel

- Current rating: 1A (AWG #28 to #32)

- Voltage rating: 125V AC, DC

Product Detail

Product Tags

| Technical Specifications |

| Specifications |

| Series: STC-001254001 Series

Contact Pitch: 1.25mm No. of Contacts: 2 to 16, 20, 30 positions Current: 1A (AWG #28 to #32) Compatible: Cross Molex 51146 Connector Series |

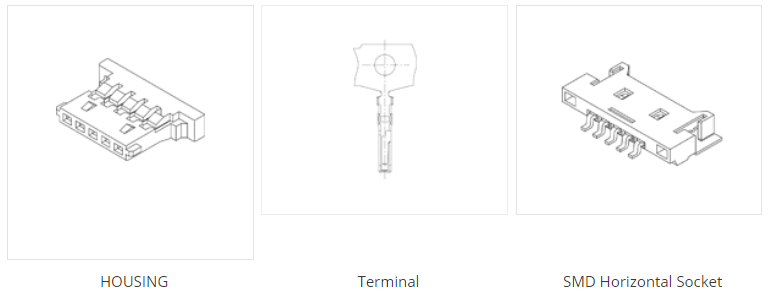

| Select Components |

|

| Cable Assemblies Refer |

|

| General Specification |

| Current Rating: 3A

Voltage Rating: 250V Temperature Range: -20°C~+85°C Contact Resistance: 20m Omega Max Insulation Resistance: 1000M Omega Min Withstanding Voltage: 1000V AC/minute |

| Overview |

Molex's 1.25mm Panel-Mate™ System Connector

|

| Features |

Offers Less Space, Ultra Low Design FeaturesSTC offers this 1.25 pitch Panel-Mate connector with overall dimensions of 6.2 mm x 9.47 mm x 1.8 mm with a mated height profile of 1.90 mm. Variation in the Number of CircuitsSTC also offers a variety of models for this connector with different numbers of circuits ranging from 2 to 16, 20, and 30 which would suit your specific needs. Durable Product DesignNo alloy was used in fastening the wires to the board but the use of a crimping method was, which made it more flexible and mechanically stronger. The crimps are well-engineered to be air-tight, preventing oxygen and moisture from reaching the metals and causing corrosion. Thus, the connector can be easily removed from the head without holding the wires. Furthermore, it prevents the cables from being easily disconnected due to entangled routing, heavy loads, or vibration Robust TerminalReliable electrical connection, even under conditions of low current and low voltage, is guaranteed with its two-point contact design. Optimized Safety Feature for Electrical Shock HazardWith its improved product enhancement, the connector has the capability of withstanding a voltage of 500 V AC per minute, which means that the insulation is sufficient to protect the user from electrical shock, overheating, and fire. Material and FinishThe header contact is made up of copper alloy, tin plated over a phosphor bronze material. The housing is made of Nylon66 UL94V-0 natural ivory. These housings are available with or without protrusions. The wafer is made up of Nylon66/46 UL94V-0. The solder tabs are made up of brass, copper undercoated, or tin-plated. Surface Mount Option with Strong Solder TabsThe two solder tabs ensure the retention of the header to PCB connection and act as a strain relief for the SMT solder tails minimizing the chance of solder joint breakage. Temperature range, insulation, and contact resistanceA special feature of the 1.25mm pitch connector is it can withstand lower temperature settings than the 0.8mm pitch connector and 1.0mm pitch connector which makes it more suitable for equipment that experiences a wide range of temperature differences. The temperature range for this connector is -40 degrees centigrade to +85 degrees centigrade. This range is based on the rise of temperature with increasing current. Insulation resistance and contact resistance are 100 M Omega per minute minimum and 20M Omega maximum, respectively. Superfine wires are usableThe connector can be used with the wires of AWG within the range of #26 to #32. This applies to wire diameters as small as 0.22mm to 0.4mm. Superfine wires such as these can help the routing job. Shrouded HeaderThe pin header of the connector is wrapped with a thin plastic guide box around it good for preventing cable connection mishaps and it also provides good guidance for the mating connector. Twin U-slot/Tuning Fork Style Contact DesignTwin U-slot section or twin-axial cable or tuning-fork style has a pair of insulated conductors where the conductors run parallel with one another. This is commonly used in high-speed balanced-mode multiplexed transmission in large computer systems, in which the signals are carried by both conductors in a U-shaped configuration. This ensures reliable connection and provides greater noise immunity.

|

| Advantages |

Compact and Denser DesignAs compared with the Molex 1.25mm Pico-Blade, the 1.25mm Panel-Mate is manufactured with lesser infill housing making it denser, more flexible, and less rigid than the Pico-Blade connector. With its very thin receptacle design, the 1.25 mm pitch Panel-Mate serves as the best choice for flat panel displays. Capable of Delivering High Resolution for Portable Gadgets DisplaysSince its popularity in flat panel displays became a rave in the modern consumer electronics industry, the 1.25mm Panel-Mate connector plays a vital role in producing high-resolution displays in portable consumer products such as tablets, smartphones, digital cameras, camcorders, point-and-shoot cameras, and pocket video cameras. Safe and Reliable1.25mm pitch connectors ensure safety, system protection, and performance with its bonded metallic conduits and multiple grounding points preventing fire hazards, component damage, overheating, and possible electrocution. The product does not contain restricted chemicals in concentrations not comply with ROHS standards. Thus, for its components, the products can be worked upon at high temperatures required by lead-free soldering.

|

| Application |

Thin and Lightweight Consumer Electronics1.25 mm Panel-Mate Connector finds its advantage in devices such as: --Tablet computers --Video games --Slate --Mini Tablet --Camcorder --Flat Panel TV Screens --Touch Panel Medical Equipment1.25 mm Panel-Mate Connector finds its advantage in the following medical equipment such as: --Plasma display panel (PDP) --Surgical Display --Operating room display --Active-matrix liquid-crystal display (AMLCD) --Rear projection: Digital Light Processing (DLP), LCD, LCOS --Electronic paper: E Ink, Gyricon --Light-emitting diode display (LED) --Active-matrix organic light-emitting diode (AMOLED) --Quantum dot display (QLED) |